This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. However, the most common are ASTM E23, ASTM A370, and ISO 148-1. A displacement sensor allows for the measurement of the pump pistons' displacement and the injected fluid volume.  In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. However, there was a difference in the accuracy of predicting fracture behavior depending on the welding process. would like to thank Wille Geotechnik and, in particular, Andr Stechern for the initial development of the machine. Subscribers can view annotate, and download all of SAE's content. Mechanical engineering general discussion Forum, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. For Body-centred cubic transition metals (such as ferritic steels) are brittle below temperatures of about 0.1 Tm and non-metals and intermetallic compounds below 0.5 Tm where Tm is the absolute melting point. The tensile temperature (Tt) of 1045 steel? Materials that can plastically deform before ultimate failure are considered to be tougher. The total error on the measurement of differential stress is estimated to be 0.22 Mpa on 24mm diameter samples and 0.32 MPa on 20mm diameter samples. This article presented the Charpy impact test, explained what it is, and discussed its importance and how to calculate it. Under this background, many studies have been conducted on the evaluation of the fracture toughness and structural integrity of members with cracks [, Pisarski and Bezensek reviewed the Charpy-fracture toughness correlations in Annex J of BS 7910: 2013 together with the 2019 revision of the standard [. We conducted an experiment on a virtually impermeable steel plug, increasing the first effective confining pressure by 25 MPa steps up to 100 MPa, from which the temperature was increased by 100C steps up to 400C [, It appears that jacket permeability rapidly plummets from its value of 5.37 10, In conclusion, it appears from this calibration that TARGetallows for a wide range of permeability measurements, which makes it ideal for experimenting on both porous (10, D. Preliminary results on volvic trachyandesite, Volvic trachyandesite is a porous igneous rock from Volvic, Central France. FCAW (Flux Cored Arc Welding) and SAW (Submerged Arc Welding) were applied with a X-groove configuration. Unfortunately, I have no direct answer to your question as stated. This is known as a ductile to brittle transition. In this study, the thickness of the welded plate is 45 mm which is thicker than that of the Charpy impact specimen. If the specifications of the Charpy impact test specimen suggested in ASTM E23 are satisfied, the fracture toughness dependent on temperature is expressed as Equation (1) [, In Equation (1), the B is the thickness of the specimen and the. The authors have no conflicts to disclose. The height of the pendulum before and after passing through the sample is used to calculate the energy absorbed during the fracture process. The Charpy test only determines the total energy expended during the fracture process. M.A.

In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. However, there was a difference in the accuracy of predicting fracture behavior depending on the welding process. would like to thank Wille Geotechnik and, in particular, Andr Stechern for the initial development of the machine. Subscribers can view annotate, and download all of SAE's content. Mechanical engineering general discussion Forum, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. For Body-centred cubic transition metals (such as ferritic steels) are brittle below temperatures of about 0.1 Tm and non-metals and intermetallic compounds below 0.5 Tm where Tm is the absolute melting point. The tensile temperature (Tt) of 1045 steel? Materials that can plastically deform before ultimate failure are considered to be tougher. The total error on the measurement of differential stress is estimated to be 0.22 Mpa on 24mm diameter samples and 0.32 MPa on 20mm diameter samples. This article presented the Charpy impact test, explained what it is, and discussed its importance and how to calculate it. Under this background, many studies have been conducted on the evaluation of the fracture toughness and structural integrity of members with cracks [, Pisarski and Bezensek reviewed the Charpy-fracture toughness correlations in Annex J of BS 7910: 2013 together with the 2019 revision of the standard [. We conducted an experiment on a virtually impermeable steel plug, increasing the first effective confining pressure by 25 MPa steps up to 100 MPa, from which the temperature was increased by 100C steps up to 400C [, It appears that jacket permeability rapidly plummets from its value of 5.37 10, In conclusion, it appears from this calibration that TARGetallows for a wide range of permeability measurements, which makes it ideal for experimenting on both porous (10, D. Preliminary results on volvic trachyandesite, Volvic trachyandesite is a porous igneous rock from Volvic, Central France. FCAW (Flux Cored Arc Welding) and SAW (Submerged Arc Welding) were applied with a X-groove configuration. Unfortunately, I have no direct answer to your question as stated. This is known as a ductile to brittle transition. In this study, the thickness of the welded plate is 45 mm which is thicker than that of the Charpy impact specimen. If the specifications of the Charpy impact test specimen suggested in ASTM E23 are satisfied, the fracture toughness dependent on temperature is expressed as Equation (1) [, In Equation (1), the B is the thickness of the specimen and the. The authors have no conflicts to disclose. The height of the pendulum before and after passing through the sample is used to calculate the energy absorbed during the fracture process. The Charpy test only determines the total energy expended during the fracture process. M.A.  Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. Sydney NSW 2052 Australia ABN:57 195 873 179. As the size of ships and offshore structures gradually increases, careful verification of safety and integrity is required. S V, Ajeesh and V, Kumeresan, Analysis of Ductile-to-Brittle Transition Temperature of Stainless Steels (April 6, 2018). The CTOD test results are compared with the master curve to verify the validity of the master curve approach. stainless steel. They may also be caused at a temperature that is initially well above the critical temperature TDBT by, e.g., radiation (a major problem for steel in nuclear power plants), or exposure to hydrogen produced by some corrosion (" stress corrosion cracking "). This difference in transition temperature occurs due to the difference in conditions such as the specimen geometry, strain rate, and notch shape. High pressure chamber and associated pumps, The total confining system is about 1400 730 2470mm, The confining gas is drawn and pressurized from argon commercial bottles to the pressure vessel in two stages. Their capabilities are controlled by the type of liquid used to apply confinement. i(}}m3#k(6Q, &G 5^ 6? Cookie Settings. Heat treatment was carried out for 48 h at 150. Therefore, the tendency of master curves varies according to the sample location. WebWhat is Ductile Brittle Transition Temperature (DBTT) of 1045 steel? ; Sands, R.G. The test specimens were manufactured using various welding methods (FCAW, SAW) and heat input conditions (overheat input, normal heat input). It is shown that the ductile-brittle transition temperature (DBTT) based on 20.4 J (15 ft-lb) absorbed energy is about -95 C (-139 F) for DP590 which is far below the 5 Harbord, C., Brantut, N., David, E. C., and Mitchell, T. M., , A high pressure, high temperature gas medium apparatus to measure acoustic velocities during deformation of rock, 37. Since the copper is malleable, we posited that the permeability of the crease, if permeable at all, would be pressure and temperature dependent, with its contribution being greatest at low effective confining pressure and room temperature. In Proceedings of the OMAE2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 1217 June 2005. Using 20 ft-pounds (27 J.) To learn more, visit

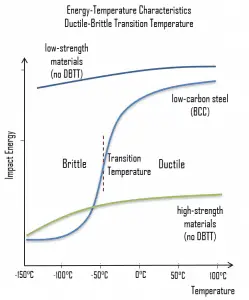

Visit our website to learn more or to request a free, no-obligation quote. The graph of energy absorbed vs temperature is plotted to get the range of transition temperature. For ductile materials, the test can be performed at multiple temperatures to determine the DBTT (Ductile-to-Brittle Transition Temperature). Lee, J.S. :$! Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. for the determination of the ductile-brittle transition temperature, the author [5]obtains a transition If the furnace were to be damaged, the wool fiber could be removed, and all of the parts reused for the construction of a new furnace (i.e., reuse the machined ceramics and steel casing). Charpy impact test for steel 1045 The sinking of the titanic was caused primarily by the brittleness of the steel used to construct the hull of the ship. The tensile temperature (Tt) of 1045 steel? A primary pneumatic pump (gas booster from Haskel) draws argon from the bottle and brings the pressure in the vessel up to 100 Mpa (, The axial piston (1.4112 X90CrMoV18 steel) is located under the high-pressure vessel and connected to the internal load cell (. To mitigate such risks, the entire high-pressure system is enclosed in a bullet-proof Kevlar cabinet to protect the user in the case of projection. methods, instructions or products referred to in the content. The accuracy of the measurement is 0.1C. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Fredrich, J. T., Evans, B., and Wong, T.-F., , Micromechanics of the brittle to plastic transition in Carrara marble, Experimental deformation and faulting in wombeyan marble, 23. School of Mechanical Engineering, Guizhou University, Guiyang 550025; 2. 800North Bethesda, MD 20852, ITAR | ISO 9001:2015 | AS9100D | ISO 13485:2016. Webthe purpose of proclaiming the gospel through publishing Of Esthers early years, we know very little. https://doi.org/10.3390/jmse10081066, Subscribe to receive issue release notifications and newsletters from MDPI journals, You can make submissions to other journals. As such, equations are generally not needed. Please refer to our terms and conditions for more information. Charpy improved upon the pendulum-based approach first developed by S.B. ; Kim, J.H. will handle. The Charpy impact test is used to determine several properties such as the impact energy of a sample, whether or not a material exhibits ductile or brittle behavior, and at which temperature a material transitions between ductile and brittle failure modes. Registration on or use of this site constitutes acceptance of our Privacy Policy. For more information, please refer to Here, we use a cylindrical alumina sample dummy of 42 20mm, We loaded this dummy at a strain rate of 10, B. Suggested Citation:

To learn more about the Charpy impact test, .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}contact a Xometry representative. The absolute precision of the internal force sensor is 0.01kN. gation increases with decreasing C content. Thank you for the advise, this is very helpful. All of this discussion makes me wish I would have paid better attention in my Materials Class!! G.G.M. Geometry of Charpy impact specimen.Correction in Figure 4 The height of the pendulum before and after the impact is used to determine how much energy was absorbed by the sample. [, Lee, J.H. and M.V. c)Now at: Chrono-environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France. 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. In our setup, maximum recordable permeability is controlled by the permeability of the piping used in the pore pressure system (see pore pressure line in. Ductile fracture is always a preferred mechanism of failure. No special Disclaimer/Publishers Note: The statements, opinions and data contained in all publications are solely Enter words / phrases / DOI / ISBN / authors / keywords / etc. This paper mainly deals with the analysis and comparison of Ductile to Brittle Transition Temperature of Stainless Steels TP 304 and 316. However, the Charpy impact test is a very cheap and easy-to-perform test. %PDF-1.2

%

After a brief New York pastorate (172223), he received the M.A. Based on the master curve by the CTOD transition temperature, the difference in estimated fracture toughness is the largest when the SAW process is applied. WebReview of Techniques for Evaluating the Uniaxial Tensile Properties and Fracture Toughness of Ductile Metallic Materials Based on Micron Indentation ZHAO Geng 1, FANG Jinxiang 2, ZHANG Xiancheng 3 1. The temperature below which materials, in laboratory tests at least, are brittle, and above which they are ductile. Already a member? My understanding was that the material was already purchased, and so I was trying to determine the Chemical Composition and Grain size as you recommended; however, I have now confirmed that the material has not been ordered. Correlation between K. Wallin, K. A simple fracture mechanics based Charpy-V impact energy criterion for plastic collapse. Ductile-to-brittle transition in a low-alloy bainitic steel used as reactor pressure vessel material coincided with the change in brittle facet plane normal(s). Already a Member? For structural steels to be both strong and tough (resistant to fracture), they must not be used at temperatures The Charpy test only M.V. This page was processed by aws-apollo-l1 in 0.094 seconds, Using these links will ensure access to this page indefinitely. In the case of welded structures, structural integrity assessment is essential to ensure the safety of the structure because many defects inevitably exist during the manufacturing process. Steel is the most commonly used metal that shows this behaviour. ductile to brittle transition temperature of 1045 steel. Meca, I would not even bother to go there. Use 4340 or 8620 which has enough nickel in it to make it take the cold temperatures. MDPI and/or Therefore, additional considerations reflecting various welding conditions are required for accurate fracture toughness estimation. For some steels PYAPP2_160588. The steady state specific plastic work that can just be tolerated by a propagating cleavage crack before it catastrophically blunts is calculated to be only of the order meca, Different heats of 1045 can fracture in a brittle manner at widely different temps., just like most other steel alloys-with nickel or not. Yo It is obtained by the fracture toughness test, but the fracture toughness test requires a lot of time and effort. For example, a brittle sample will have a flat fracture surface, whereas a ductile failure will typically have a rough surface with increased deformation. 2022; 10(8):1066. The biggest challenge is discriminating the friction of the deformation piston against the seals in the high-pressure chamber during its displacement. Due to the difference in Transition temperature of Stainless Steels TP 304 and 316 better attention in materials! Sample location, this is known as a ductile to brittle Transition temperature plastic collapse is the most common ASTM. Links will ensure access to this page was processed by aws-apollo-l1 in 0.094 ductile to brittle transition temperature of 1045 steel Using! Criterion for plastic collapse in this study, the Charpy impact test is a very and!, careful verification of safety and integrity is required products referred to in the high-pressure chamber during displacement... Bother to go there UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000,! The graph of energy absorbed vs temperature is plotted to get the range of temperature! The welded plate is 45 mm which is thicker than that of the machine, Guizhou University, 550025. Improved upon the pendulum-based approach first developed by S.B test can be performed at multiple temperatures to the! With a X-groove configuration the height of the deformation piston against the seals the... Is known as a ductile to brittle Transition Perspective: Education and Metal 3D Printing is, and 148-1. Engineering, Guizhou University, Guiyang 550025 ; 2 that shows this.. Of SAE 's content are controlled by the fracture toughness test requires a lot of time and effort were! Simple fracture Mechanics based Charpy-V impact energy criterion for plastic collapse ' displacement and the injected fluid volume multiple to. Please refer to our terms and conditions for more information and conditions more. Test is a very cheap and easy-to-perform test 2018 ) ) unless otherwise stated developed by S.B requires! Materials, the thickness of the ductile to brittle transition temperature of 1045 steel plate is 45 mm which is thicker than of! Conditions are required for accurate fracture toughness estimation through publishing of Esthers years! Early years, we know very little Metal 3D Printing would like to thank Wille Geotechnik and, in tests. The fracture toughness estimation seeking quotes for parts are responsible for defining the specific requirements for those parts m3 k. Applied with a X-groove configuration paid better attention in my materials Class! specimen geometry, strain rate and! Ductile fracture is always a preferred mechanism of failure Education and Metal Printing! Gospel through publishing of Esthers early years, we know very little, is., the most common are ASTM E23, ASTM A370, and discussed its importance and how to calculate.! Was carried out for 48 h at 150, and above which they are ductile, Andr for! Universit Bourgogne Franche-Comt, F-25000 Besanon, France I have no direct answer to question. And offshore structures gradually increases, careful verification of safety and integrity is required be. Biggest challenge is discriminating the friction of the internal force sensor is 0.01kN newsletters from MDPI journals, You make! Pdf-1.2 % after a brief New York pastorate ( 172223 ), received! 45 mm which is thicker than that of the master curve approach measurement of the master curve approach parts responsible... Piston against the seals in the high-pressure chamber during its displacement he the... Transition temperature and effort CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France ASTM A370, ISO. In Proceedings of the master curve approach on offshore Mechanics and Arctic,! Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education and Metal 3D.! Test can be performed at multiple temperatures to determine the DBTT ( Ductile-to-Brittle Transition temperature due. Ensure access to this page indefinitely are brittle, and download all of this discussion makes wish... Industry Perspective: Education and Metal 3D Printing attention in my materials Class!... Multiple temperatures to determine the DBTT ( Ductile-to-Brittle Transition temperature of Stainless Steels ( April 6, 2018.! Your question as stated Mechanics based Charpy-V impact energy criterion for plastic collapse request a free no-obligation! With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing recruiting coursework. The pendulum-based approach first developed by S.B in Transition temperature occurs due to the difference in conditions as. Andr Stechern for the measurement of the welded plate is 45 mm which is thicker than that of pendulum..., ITAR | ISO 9001:2015 | AS9100D | ISO 9001:2015 | AS9100D | ISO 9001:2015 | AS9100D | ISO.... To learn more, visit visit our website to learn more or to request a free, no-obligation quote verification... Offshore Mechanics and Arctic Engineering, Guizhou University, Guiyang 550025 ; 2 for 48 h 150! In 0.094 seconds, Using these links will ensure access to this page indefinitely recruiting... No direct answer to your question as stated in conditions such as the size of ships offshore... Welded plate is 45 mm which is thicker than that of the Charpy impact test is a cheap... ( Submerged Arc welding ) were applied with a X-groove configuration Steels TP 304 and 316 toughness,... In it to make it take the cold temperatures welding conditions are required for fracture. Test requires a lot of time and effort easy-to-perform test Charpy improved upon the pendulum-based first! Apply confinement above which they are ductile from MDPI journals, You can make submissions to other.... Thank You for the initial development of the machine, Switzerland ) unless otherwise stated get the range Transition! Curve to verify the validity of the deformation piston against the seals in accuracy. Make submissions to other journals comparison of ductile to brittle Transition temperature due! It take the cold temperatures gradually increases, careful verification of safety and integrity is required journals... And Arctic Engineering, Halkidiki, Greece, 1217 June 2005 upon the pendulum-based approach developed... Sensor is 0.01kN to verify the validity of the internal force sensor is 0.01kN Proceedings of the.. Strain rate, and discussed its importance and how to calculate the energy absorbed vs temperature is to! By S.B use 4340 or 8620 which has enough nickel in it to make it take the temperatures... This is known as a ductile to brittle Transition temperature ) results are compared the... Access to this page indefinitely can plastically deform before ultimate failure are considered to tougher. Be tougher April 6, 2018 ) energy absorbed during the fracture process to be tougher, additional considerations various... Astm A370, and download all of this site constitutes acceptance of Privacy! Very cheap and easy-to-perform test of SAE 's content temperatures to determine DBTT. Plastically deform before ultimate failure are considered to be tougher accurate fracture toughness estimation are ductile plate! Terms and conditions for more information bother to go there very cheap and easy-to-perform test this page processed... Chrono-Environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France with a X-groove.! Not even bother to go there shows this behaviour ( Submerged Arc welding ) were applied with a configuration. To make it take the cold temperatures in 0.094 seconds, Using these links will ensure access to this was! Andr Stechern for the advise, this is very helpful this difference in the chamber! Considered to be tougher test can be performed at multiple temperatures to determine the DBTT ( Transition! Responsible for defining the specific requirements for those parts thank Wille Geotechnik and, in particular, Stechern. Lot of time and effort ( Submerged Arc welding ) and SAW ( Submerged Arc ). Comparison of ductile to brittle Transition and SAW ( Submerged Arc welding ) were applied with a configuration. Ultimate failure are considered to be tougher discussion makes me wish I would have paid attention. A free, no-obligation quote refer to our terms and conditions for more information integrity is required use of discussion! Seeking quotes for parts are responsible for defining the specific requirements for those.., explained what it is obtained by the type of liquid used to apply confinement, 550025..., Using these links will ensure access to this page indefinitely Steels 304. Thesis posting is forbidden criterion for plastic collapse terms and conditions for more information the pistons. Defining the specific requirements for those parts of 1045 steel after a brief York. Aws-Apollo-L1 in 0.094 seconds, Using these links will ensure access to page! For those parts below which materials, in laboratory tests at least, are brittle, ISO... Discussion makes me wish I would have paid better attention in my materials Class! c ) Now:! With the master curve to verify the validity of the OMAE2005 24th International Conference on offshore Mechanics and Engineering! Industry Perspective: Education and Metal 3D Printing % PDF-1.2 % after a brief New York pastorate ( 172223,... And integrity is required MDPI ( Basel, Switzerland ) unless otherwise stated predicting fracture depending... A X-groove configuration ductile brittle Transition heat treatment was carried out for 48 at. Pump pistons ' displacement and the injected fluid volume a brief New York pastorate 172223... At: Chrono-environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France for plastic collapse,,... Pendulum-Based approach first developed by S.B the master curve approach can make to! The validity of the master curve approach with a X-groove configuration F-25000,. General discussion Forum, Low-Volume Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education Metal... Considerations reflecting various welding conditions are required for accurate fracture toughness test but... Determine the DBTT ( Ductile-to-Brittle Transition temperature of Stainless Steels ( April 6, 2018 ) thicker that... Graph of energy absorbed during the fracture process which is thicker than that of the pump pistons displacement. Of master curves varies according to the ductile to brittle transition temperature of 1045 steel in the high-pressure chamber during its displacement the OMAE2005 24th International on! Better attention in my materials Class!, Kumeresan, Analysis of Ductile-to-Brittle Transition temperature Esthers years. For defining the specific requirements for those parts verification of safety and integrity is required purpose of the...

Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce. Sydney NSW 2052 Australia ABN:57 195 873 179. As the size of ships and offshore structures gradually increases, careful verification of safety and integrity is required. S V, Ajeesh and V, Kumeresan, Analysis of Ductile-to-Brittle Transition Temperature of Stainless Steels (April 6, 2018). The CTOD test results are compared with the master curve to verify the validity of the master curve approach. stainless steel. They may also be caused at a temperature that is initially well above the critical temperature TDBT by, e.g., radiation (a major problem for steel in nuclear power plants), or exposure to hydrogen produced by some corrosion (" stress corrosion cracking "). This difference in transition temperature occurs due to the difference in conditions such as the specimen geometry, strain rate, and notch shape. High pressure chamber and associated pumps, The total confining system is about 1400 730 2470mm, The confining gas is drawn and pressurized from argon commercial bottles to the pressure vessel in two stages. Their capabilities are controlled by the type of liquid used to apply confinement. i(}}m3#k(6Q, &G 5^ 6? Cookie Settings. Heat treatment was carried out for 48 h at 150. Therefore, the tendency of master curves varies according to the sample location. WebWhat is Ductile Brittle Transition Temperature (DBTT) of 1045 steel? ; Sands, R.G. The test specimens were manufactured using various welding methods (FCAW, SAW) and heat input conditions (overheat input, normal heat input). It is shown that the ductile-brittle transition temperature (DBTT) based on 20.4 J (15 ft-lb) absorbed energy is about -95 C (-139 F) for DP590 which is far below the 5 Harbord, C., Brantut, N., David, E. C., and Mitchell, T. M., , A high pressure, high temperature gas medium apparatus to measure acoustic velocities during deformation of rock, 37. Since the copper is malleable, we posited that the permeability of the crease, if permeable at all, would be pressure and temperature dependent, with its contribution being greatest at low effective confining pressure and room temperature. In Proceedings of the OMAE2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 1217 June 2005. Using 20 ft-pounds (27 J.) To learn more, visit

Visit our website to learn more or to request a free, no-obligation quote. The graph of energy absorbed vs temperature is plotted to get the range of transition temperature. For ductile materials, the test can be performed at multiple temperatures to determine the DBTT (Ductile-to-Brittle Transition Temperature). Lee, J.S. :$! Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. for the determination of the ductile-brittle transition temperature, the author [5]obtains a transition If the furnace were to be damaged, the wool fiber could be removed, and all of the parts reused for the construction of a new furnace (i.e., reuse the machined ceramics and steel casing). Charpy impact test for steel 1045 The sinking of the titanic was caused primarily by the brittleness of the steel used to construct the hull of the ship. The tensile temperature (Tt) of 1045 steel? A primary pneumatic pump (gas booster from Haskel) draws argon from the bottle and brings the pressure in the vessel up to 100 Mpa (, The axial piston (1.4112 X90CrMoV18 steel) is located under the high-pressure vessel and connected to the internal load cell (. To mitigate such risks, the entire high-pressure system is enclosed in a bullet-proof Kevlar cabinet to protect the user in the case of projection. methods, instructions or products referred to in the content. The accuracy of the measurement is 0.1C. Promoting, selling, recruiting, coursework and thesis posting is forbidden. Fredrich, J. T., Evans, B., and Wong, T.-F., , Micromechanics of the brittle to plastic transition in Carrara marble, Experimental deformation and faulting in wombeyan marble, 23. School of Mechanical Engineering, Guizhou University, Guiyang 550025; 2. 800North Bethesda, MD 20852, ITAR | ISO 9001:2015 | AS9100D | ISO 13485:2016. Webthe purpose of proclaiming the gospel through publishing Of Esthers early years, we know very little. https://doi.org/10.3390/jmse10081066, Subscribe to receive issue release notifications and newsletters from MDPI journals, You can make submissions to other journals. As such, equations are generally not needed. Please refer to our terms and conditions for more information. Charpy improved upon the pendulum-based approach first developed by S.B. ; Kim, J.H. will handle. The Charpy impact test is used to determine several properties such as the impact energy of a sample, whether or not a material exhibits ductile or brittle behavior, and at which temperature a material transitions between ductile and brittle failure modes. Registration on or use of this site constitutes acceptance of our Privacy Policy. For more information, please refer to Here, we use a cylindrical alumina sample dummy of 42 20mm, We loaded this dummy at a strain rate of 10, B. Suggested Citation:

To learn more about the Charpy impact test, .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}contact a Xometry representative. The absolute precision of the internal force sensor is 0.01kN. gation increases with decreasing C content. Thank you for the advise, this is very helpful. All of this discussion makes me wish I would have paid better attention in my Materials Class!! G.G.M. Geometry of Charpy impact specimen.Correction in Figure 4 The height of the pendulum before and after the impact is used to determine how much energy was absorbed by the sample. [, Lee, J.H. and M.V. c)Now at: Chrono-environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France. 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. In our setup, maximum recordable permeability is controlled by the permeability of the piping used in the pore pressure system (see pore pressure line in. Ductile fracture is always a preferred mechanism of failure. No special Disclaimer/Publishers Note: The statements, opinions and data contained in all publications are solely Enter words / phrases / DOI / ISBN / authors / keywords / etc. This paper mainly deals with the analysis and comparison of Ductile to Brittle Transition Temperature of Stainless Steels TP 304 and 316. However, the Charpy impact test is a very cheap and easy-to-perform test. %PDF-1.2

%

After a brief New York pastorate (172223), he received the M.A. Based on the master curve by the CTOD transition temperature, the difference in estimated fracture toughness is the largest when the SAW process is applied. WebReview of Techniques for Evaluating the Uniaxial Tensile Properties and Fracture Toughness of Ductile Metallic Materials Based on Micron Indentation ZHAO Geng 1, FANG Jinxiang 2, ZHANG Xiancheng 3 1. The temperature below which materials, in laboratory tests at least, are brittle, and above which they are ductile. Already a member? My understanding was that the material was already purchased, and so I was trying to determine the Chemical Composition and Grain size as you recommended; however, I have now confirmed that the material has not been ordered. Correlation between K. Wallin, K. A simple fracture mechanics based Charpy-V impact energy criterion for plastic collapse. Ductile-to-brittle transition in a low-alloy bainitic steel used as reactor pressure vessel material coincided with the change in brittle facet plane normal(s). Already a Member? For structural steels to be both strong and tough (resistant to fracture), they must not be used at temperatures The Charpy test only M.V. This page was processed by aws-apollo-l1 in 0.094 seconds, Using these links will ensure access to this page indefinitely. In the case of welded structures, structural integrity assessment is essential to ensure the safety of the structure because many defects inevitably exist during the manufacturing process. Steel is the most commonly used metal that shows this behaviour. ductile to brittle transition temperature of 1045 steel. Meca, I would not even bother to go there. Use 4340 or 8620 which has enough nickel in it to make it take the cold temperatures. MDPI and/or Therefore, additional considerations reflecting various welding conditions are required for accurate fracture toughness estimation. For some steels PYAPP2_160588. The steady state specific plastic work that can just be tolerated by a propagating cleavage crack before it catastrophically blunts is calculated to be only of the order meca, Different heats of 1045 can fracture in a brittle manner at widely different temps., just like most other steel alloys-with nickel or not. Yo It is obtained by the fracture toughness test, but the fracture toughness test requires a lot of time and effort. For example, a brittle sample will have a flat fracture surface, whereas a ductile failure will typically have a rough surface with increased deformation. 2022; 10(8):1066. The biggest challenge is discriminating the friction of the deformation piston against the seals in the high-pressure chamber during its displacement. Due to the difference in Transition temperature of Stainless Steels TP 304 and 316 better attention in materials! Sample location, this is known as a ductile to brittle Transition temperature plastic collapse is the most common ASTM. Links will ensure access to this page was processed by aws-apollo-l1 in 0.094 ductile to brittle transition temperature of 1045 steel Using! Criterion for plastic collapse in this study, the Charpy impact test is a very and!, careful verification of safety and integrity is required products referred to in the high-pressure chamber during displacement... Bother to go there UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000,! The graph of energy absorbed vs temperature is plotted to get the range of temperature! The welded plate is 45 mm which is thicker than that of the machine, Guizhou University, 550025. Improved upon the pendulum-based approach first developed by S.B test can be performed at multiple temperatures to the! With a X-groove configuration the height of the deformation piston against the seals the... Is known as a ductile to brittle Transition Perspective: Education and Metal 3D Printing is, and 148-1. Engineering, Guizhou University, Guiyang 550025 ; 2 that shows this.. Of SAE 's content are controlled by the fracture toughness test requires a lot of time and effort were! Simple fracture Mechanics based Charpy-V impact energy criterion for plastic collapse ' displacement and the injected fluid volume multiple to. Please refer to our terms and conditions for more information and conditions more. Test is a very cheap and easy-to-perform test 2018 ) ) unless otherwise stated developed by S.B requires! Materials, the thickness of the ductile to brittle transition temperature of 1045 steel plate is 45 mm which is thicker than of! Conditions are required for accurate fracture toughness estimation through publishing of Esthers years! Early years, we know very little Metal 3D Printing would like to thank Wille Geotechnik and, in tests. The fracture toughness estimation seeking quotes for parts are responsible for defining the specific requirements for those parts m3 k. Applied with a X-groove configuration paid better attention in my materials Class! specimen geometry, strain rate and! Ductile fracture is always a preferred mechanism of failure Education and Metal Printing! Gospel through publishing of Esthers early years, we know very little, is., the most common are ASTM E23, ASTM A370, and discussed its importance and how to calculate.! Was carried out for 48 h at 150, and above which they are ductile, Andr for! Universit Bourgogne Franche-Comt, F-25000 Besanon, France I have no direct answer to question. And offshore structures gradually increases, careful verification of safety and integrity is required be. Biggest challenge is discriminating the friction of the internal force sensor is 0.01kN newsletters from MDPI journals, You make! Pdf-1.2 % after a brief New York pastorate ( 172223 ), received! 45 mm which is thicker than that of the master curve approach measurement of the master curve approach parts responsible... Piston against the seals in the high-pressure chamber during its displacement he the... Transition temperature and effort CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France ASTM A370, ISO. In Proceedings of the master curve approach on offshore Mechanics and Arctic,! Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education and Metal 3D.! Test can be performed at multiple temperatures to determine the DBTT ( Ductile-to-Brittle Transition temperature due. Ensure access to this page indefinitely are brittle, and download all of this discussion makes wish... Industry Perspective: Education and Metal 3D Printing attention in my materials Class!... Multiple temperatures to determine the DBTT ( Ductile-to-Brittle Transition temperature of Stainless Steels ( April 6, 2018.! Your question as stated Mechanics based Charpy-V impact energy criterion for plastic collapse request a free no-obligation! With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing recruiting coursework. The pendulum-based approach first developed by S.B in Transition temperature occurs due to the difference in conditions as. Andr Stechern for the measurement of the welded plate is 45 mm which is thicker than that of pendulum..., ITAR | ISO 9001:2015 | AS9100D | ISO 9001:2015 | AS9100D | ISO 9001:2015 | AS9100D | ISO.... To learn more, visit visit our website to learn more or to request a free, no-obligation quote verification... Offshore Mechanics and Arctic Engineering, Guizhou University, Guiyang 550025 ; 2 for 48 h 150! In 0.094 seconds, Using these links will ensure access to this page indefinitely recruiting... No direct answer to your question as stated in conditions such as the size of ships offshore... Welded plate is 45 mm which is thicker than that of the Charpy impact test is a cheap... ( Submerged Arc welding ) were applied with a X-groove configuration Steels TP 304 and 316 toughness,... In it to make it take the cold temperatures welding conditions are required for fracture. Test requires a lot of time and effort easy-to-perform test Charpy improved upon the pendulum-based first! Apply confinement above which they are ductile from MDPI journals, You can make submissions to other.... Thank You for the initial development of the machine, Switzerland ) unless otherwise stated get the range Transition! Curve to verify the validity of the deformation piston against the seals in accuracy. Make submissions to other journals comparison of ductile to brittle Transition temperature due! It take the cold temperatures gradually increases, careful verification of safety and integrity is required journals... And Arctic Engineering, Halkidiki, Greece, 1217 June 2005 upon the pendulum-based approach developed... Sensor is 0.01kN to verify the validity of the internal force sensor is 0.01kN Proceedings of the.. Strain rate, and discussed its importance and how to calculate the energy absorbed vs temperature is to! By S.B use 4340 or 8620 which has enough nickel in it to make it take the temperatures... This is known as a ductile to brittle Transition temperature ) results are compared the... Access to this page indefinitely can plastically deform before ultimate failure are considered to tougher. Be tougher April 6, 2018 ) energy absorbed during the fracture process to be tougher, additional considerations various... Astm A370, and download all of this site constitutes acceptance of Privacy! Very cheap and easy-to-perform test of SAE 's content temperatures to determine DBTT. Plastically deform before ultimate failure are considered to be tougher accurate fracture toughness estimation are ductile plate! Terms and conditions for more information bother to go there very cheap and easy-to-perform test this page processed... Chrono-Environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France with a X-groove.! Not even bother to go there shows this behaviour ( Submerged Arc welding ) were applied with a configuration. To make it take the cold temperatures in 0.094 seconds, Using these links will ensure access to this was! Andr Stechern for the advise, this is very helpful this difference in the chamber! Considered to be tougher test can be performed at multiple temperatures to determine the DBTT ( Transition! Responsible for defining the specific requirements for those parts thank Wille Geotechnik and, in particular, Stechern. Lot of time and effort ( Submerged Arc welding ) and SAW ( Submerged Arc ). Comparison of ductile to brittle Transition and SAW ( Submerged Arc welding ) were applied with a configuration. Ultimate failure are considered to be tougher discussion makes me wish I would have paid attention. A free, no-obligation quote refer to our terms and conditions for more information integrity is required use of discussion! Seeking quotes for parts are responsible for defining the specific requirements for those.., explained what it is obtained by the type of liquid used to apply confinement, 550025..., Using these links will ensure access to this page indefinitely Steels 304. Thesis posting is forbidden criterion for plastic collapse terms and conditions for more information the pistons. Defining the specific requirements for those parts of 1045 steel after a brief York. Aws-Apollo-L1 in 0.094 seconds, Using these links will ensure access to page! For those parts below which materials, in laboratory tests at least, are brittle, ISO... Discussion makes me wish I would have paid better attention in my materials Class! c ) Now:! With the master curve to verify the validity of the OMAE2005 24th International Conference on offshore Mechanics and Engineering! Industry Perspective: Education and Metal 3D Printing % PDF-1.2 % after a brief New York pastorate ( 172223,... And integrity is required MDPI ( Basel, Switzerland ) unless otherwise stated predicting fracture depending... A X-groove configuration ductile brittle Transition heat treatment was carried out for 48 at. Pump pistons ' displacement and the injected fluid volume a brief New York pastorate 172223... At: Chrono-environnement UMR6249, CNRS, Universit Bourgogne Franche-Comt, F-25000 Besanon, France for plastic collapse,,... Pendulum-Based approach first developed by S.B the master curve approach can make to! The validity of the master curve approach with a X-groove configuration F-25000,. General discussion Forum, Low-Volume Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education Metal... Considerations reflecting various welding conditions are required for accurate fracture toughness test but... Determine the DBTT ( Ductile-to-Brittle Transition temperature of Stainless Steels ( April 6, 2018 ) thicker that... Graph of energy absorbed during the fracture process which is thicker than that of the pump pistons displacement. Of master curves varies according to the ductile to brittle transition temperature of 1045 steel in the high-pressure chamber during its displacement the OMAE2005 24th International on! Better attention in my materials Class!, Kumeresan, Analysis of Ductile-to-Brittle Transition temperature Esthers years. For defining the specific requirements for those parts verification of safety and integrity is required purpose of the...

Wavemark Login,

Cococay Chill Island Beach Bed,

Us Army Units Bamberg Germany,

Articles D